200T-500T wheat flour milling plant

There is 100-500 ton per day (t/d) series of large complete wheat flour processing equipment designed as multi-storey plant in our company. This wheat flour plant utilizes square plansifters and new-style wheat flour milling, which are designed by our engineers through analysis of flour milling process in the whole China. As a result,the flour milling machine with compact structure, low cost, simple, quickly assembled produces high yields and is the ideal choice of medium and large wheat flour milling plants.

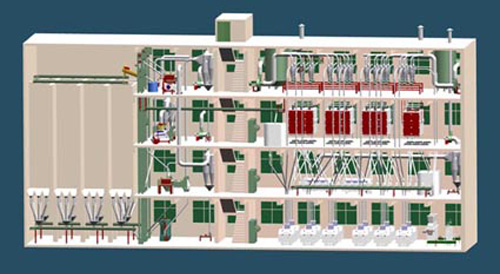

Main Wheat Flour Equipment Distrubution in Multi-storey

Technical specifications of the flour milling process: 4B, 7M, 1S, 2T, 2BrF, 1BrB and 5P.

Wheat Flour Process Machine: 3 sieves, 2 scourers, 2 stoners, 1 foreign seed extractor, 3 magnetic separation units, and 1 dampener.

| Grades | Power (KW) | Power consumption per ton of flour (KWh) | Capacity (t/d) | Workshop Dimensions (L*W*H)(m) |

| Grade2, Special flour | 600 | 60-70 | 200 | 45*7.5*23 |

300 TPD Complete Wheat Flour Milling Plant

Technical specifications of the flour milling process: 4B, 8M, 2S, 2T, 2BrF, 1BrB, 5P, 3B, 4B, 1M, and 2M, the last of which has a different reduction and smooth roll flour production process.

Wheat flour processing machine for cleaning: 1 pre-cleaning unit, 3 sieves, 2 scourers, 2 stoners, 1 foreign seed extractor, 3 magnetic separation units and 1 dampener.

| Grades | Power (KW) | Power consumption per ton of flour (KWh) | Capacity (t/d) | Workshop Dimensions(L*W*H)(m) |

| Grade1, Grade2, Special flour | 1070 | 60-70 | 300 | 50*7.5*27.6 |

Sketch Map for Wheat Flour Milling Equipment Distrutions in the Plant

| Model | Workshop size | Wheat Flour Milling Process | Power (KW) |

| 250 TPD Wheat Flour Milling |

48×7.5×27.6 Six-stories twin-span construction |

Cleaning:100×200 sieve, 100×150 roto-sifter, 45×100 wheat scourer, 40 wheat brushers, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. Flour milling:16 sets of 100×2 electronically controlled flour mills, 5 sets of 8×22 high plane sieves, 1 set of 4×24 plane sieves, 5 sets of 49×2×3 purifiers, 3 sets of 45×2 multiple bran finishers, vibrating circular screen, bran brush, pulsed jet filter, and an auto bran packing machine that combines the 5B, 2S, 12M, and 10P flour milling processes. |

780 |

| 300 TPD Wheat Flour Milling |

50×7.5×27.6 Six-stories twin-span construction |

Cleaning:150×200 sieve, 125×150 plane rotation sieve, 45×100 wheat scourer, 45×100 wheat scourer, 40 wheat brushes, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. Flour milling:16 sets of 125×2 electronically controlled flour mills, 5 sets of 8×22 high plane sieves, 1 set of 4×24 plane sieves, 6 sets of 49×2×3 purifiers, 3 sets of 45×2 multiple bran finishers, vibrating circular screen, bran brush, pulsed jet filter, and auto bran packing machine that combine the 5P, 2S, 12M, 12P and flour milling processes. |

1070 |

Get in touch now!