rice bran oil manufacturing process

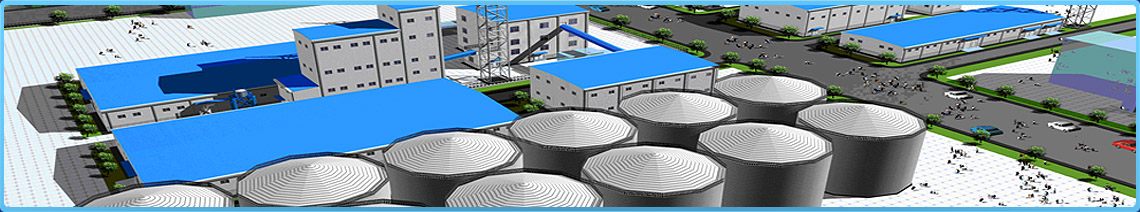

As a kind of popular cooking oil, rice bran oil is extracted from the germ and the inner husk of rice. It is noble for its high smoke point and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. What’s more, eating rice bran oil helps lower cholesterol, fight diseases, enhance the immune system, and fight free radicals and more. Rice bran oil manufacturing processes mainly includes rice bran oil expelling, extraction and refining.

Rice bran oil expelling relies on high quality rice bran oil expellers. After the well prepared rice bran is put into the feeder of the expeller, a screw worm will transport the rice bran advance. As the screw worm moves, the space becomes smaller and smaller, thus squeezing rice bran oil out. Then the fresh rice bran oil seeps out through the small openings in the bottom of the squeezing barrel where the rice bran oil cake cannot pass through, and thus separating rice bran oil from oil cake.

After collecting rice bran oil cake, rice bran oil extraction comes with the help of food grade solvent, usually hexane. Rice bran oil extraction works on the principle of counter current and moving bed with variable bed height and different speed mechanism to ensure the permit of excellent penetration and percolation of solvent for absolute extraction. Then the distillation begins in the vacuum, and the extracted rice bran oil is collected by vaporizing solvent out for later recovery.

What part of rice is rice bran?

Rice bran is the thin layer of brown rice. It is the most nutritious part of rice. Rice bran is high in vitamins and nutrients. Rice bran oil, not fiber, lowers cholesterol in healthy, moderately hypercholesterolemic individuals. Because there were no substantial differences in the fatty acid composition of the diets, the reduction of cholesterol seen was due to other component present in the rice bran oil. Rice bran oil is used in cosmetics because it's a great moisturizer. It contains natural Vitamin E, flows nicely. It provides moderate penetration and leaves no greasiness or stickiness on the skin. It is an excellent carrier oil.

Then the rice bran oil is pumped into the refining machinery to produce different grades of rice bran oil. The refining process usually includes: filtering, neutralization, degumming, decolorization, deodorization, and dewax, etc.

After all these manufacturing processes, fresh rice bran oil would be ready.

Get in touch now!