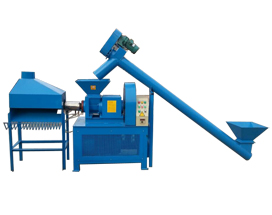

sawdust briquetting machine

Sawdust is the commonest so called rubbish in sawmill, but it is good biomass material. Briquetting is a way to convert loose biomass materials, such as sawdust, straw, and rice husks into high density solid blocks that can be used as efficient fuel. Sawdust is one of the best materials for high pressure briquetting mainly because sawdust contains a high proportion of lignin, which functions as glue when briquetting, and that sawdust doesn’t need to be ground before briquetting.GCBA Series Briquetting Machine

Briquetting machine is also known as briquette making machine. GCBA series briquetting machine is screw type design. It can be used to make quadrangular or hexagonal cylinder and throughout the boy there is a 15-20mm hole. These briquettes are quite convenient to be stacked and they are more efficient when burning because of the carbonized outer layer and central hole.GCBA series briquetting machine equipped with automatic temperature control system is widely applied to extrude biomass or high density wood materials (sawdust, straw, rice husk, etc) into bio-fuel briquettes. The motor of this machine can be 1kw/15kw/18.5kw/22kw-3phase-380v-50hz electrical driven.

| Model | GCBA-I |

|

| Output capacity kg/h | 180-210 kg/h | |

| Motor Power (kw) | 15kw | |

| Electric heater (kw) | 6kw | |

| Size of briquettes | Dia.50mm | |

| Size of inside hole | Dia.16mm | |

| Density of briquettes | 1.3 g/cm3 | |

| Weight(kg) | 585kg | |

| Warranty | 12 Months | |

| Overall dimension(mm) | 1700*750*1280 mm |

| Model | GCBA-II |

|

| Output kg/h | 300~350 kg/h | |

| Motor Power (kw) | 22 kW | |

| Electric heater (kw) | 9 kw | |

| Size of briquettes | Dia.70mm | |

| Size of inside hole | Dia.20mm | |

| Density of briquettes | 1.3 g/cm3 | |

| Weight(kg) | 1300 kg | |

| Overall dimension(mm) | 1960*880*1620 mm | |

| Warranty | 12 Months |

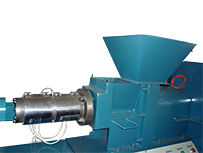

GCBC Series Briquetting Machine

GCBC Series briquette making machine is a kind of high-end briquetting equipment. It is improved in both appearance design and structure design based on 6 years of research and manufacturing experience. Do not need to change Inner Former until input capacity exceed 1000 tons.

| Model | GCBC- I |

|

| Output capacity kg/h | 180-210 | |

| Motor Power (kw) | 15 | |

| Electric heater (kw) | 2.2kw*2 | |

| Life of the inner former | 1-2years | |

| Size of briquettes | Dia.50mm*L.480mm | |

| Size of inside hole | Dia.16mm | |

| Density of briquettes | 1.3 g/cm3 | |

| Weight(kg) | 700kg | |

| Overall dimension(mm) | 2700*600*1600 mm |

| Model | GCBC-II |

|

| Output capacity kg/h | 300-350 | |

| Motor Power (kw) | 18.5kw | |

| Electric heater (kw) | 2.2kw×2 | |

| Life of the inner former | 1-2years | |

| Size of briquettes | Dia.60mm*L.500mm | |

| Size of inside hole | Dia.16mm | |

| Density of briquettes | 1.3 g/cm3 | |

| Weight(kg) | 1000kg | |

| Overall dimension(mm) | 2000*600*1700 mm |

Features of GCBC Series Briquette Making Machine:

|

|

|

|

|

|

|

|

|

|

|

|

Sawdust briquettes have many advantages. Sawdust briquettes are clean and tidy, and easy to transport and store. They are of high density, and release lasting energy. Besides, conversion of sawdust into combustible biomass briquettes will provide a good way to meet individual energy needs while alleviating landfill use. Moreover, lumber has become a scarce resource in many areas of the world, and there is an urgent need to use sustainable fuels to augment or replace traditional wood fuels or traditional fossil fuels. What’s more, sawdust briquettes are environmentally friendly, and release less poisonous gas or greenhouse gases. Further, their ash after burning can be used as fertilizer. Sawdust briquettes have a wider and wider application in industrial boilers as well as in home heating and cooking.

Briquetting sawdust is pretty profitable with good sawdust briquetting machines. Our sawdust briquetting machines have been exported to many countries and earned good reputations worldwide. If you want to buy the high quality sawdust briquetting machine with reasonable price, we are exactly what you are looking for!

Get in touch now!